Replacing rear brakes is an essential maintenance task that can save you money and ensure your vehicle’s safety. While it may seem daunting, with the right tools and knowledge, you can perform this task at home. This guide will walk you through the process of replacing rear brake pads and rotors, providing you with step-by-step instructions and valuable tips to complete the job successfully.

Rear brake replacement typically involves changing the brake pads and, if necessary, the rotors. The frequency of replacement depends on your driving habits and the type of vehicle you own. On average, brake pads need replacement every 30,000 to 70,000 miles, while rotors can last anywhere from 50,000 to 70,000 miles. Regular inspection and timely replacement are crucial for maintaining optimal braking performance and safety.

Before you begin, it’s important to gather all the necessary tools and parts. Here’s a quick overview of what you’ll need:

| Tools | Parts |

|---|---|

| Jack and jack stands | New brake pads |

| Lug wrench | New rotors (if needed) |

| C-clamp or caliper piston tool | Brake lubricant |

| Socket set and wrenches | Brake cleaner |

| Wire brush | New hardware (if needed) |

Now that you have an overview of the task and the necessary equipment, let’s dive into the step-by-step process of replacing your rear brakes.

Preparation and Safety Measures

Before you start working on your vehicle’s brakes, it’s crucial to prioritize safety. Begin by parking your car on a flat, level surface. Engage the parking brake and place wheel chocks in front of the front tires to prevent the vehicle from rolling. Locate the jacking points specified in your vehicle’s manual and position the jack accordingly.

Once you’ve secured the vehicle, loosen the lug nuts on the rear wheels before lifting the car. This step is essential as it’s much easier to break the lug nuts loose while the wheel is still on the ground. After loosening the lug nuts, use the jack to lift the rear of the vehicle until the wheels are off the ground. Place jack stands under the designated support points for added safety.

With the car securely lifted, remove the lug nuts completely and take off the rear wheels. This will give you full access to the brake assembly. Before proceeding, it’s a good idea to spray the brake components with brake cleaner to remove any dust or debris. This step not only makes the job cleaner but also helps you inspect the parts more easily.

Safety tip: Never rely solely on a jack to support your vehicle. Always use jack stands and check their stability before working under the car.

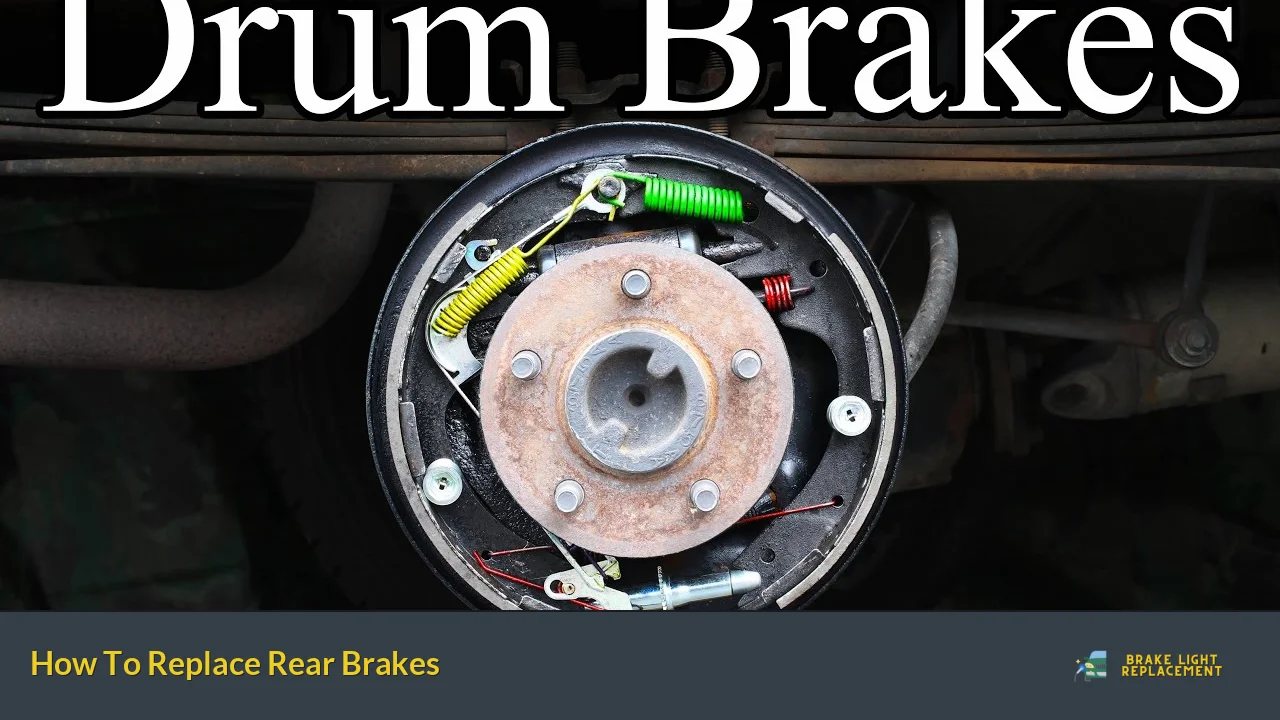

Removing the Old Brake Pads and Rotors

With the wheels removed, you’ll have a clear view of the brake caliper, pads, and rotor. Start by locating the caliper bolts. These are typically found on the back of the caliper and may require a socket or wrench to remove. Once you’ve removed the bolts, carefully slide the caliper off the rotor. Be cautious not to let it hang by the brake hose, as this can cause damage. Use a bungee cord or wire to suspend the caliper from the suspension spring.

Next, remove the old brake pads from the caliper bracket. Take note of how they’re positioned, as you’ll need to install the new pads in the same orientation. Inspect the caliper piston and ensure it moves freely. If it’s stuck or shows signs of leaking, you may need to replace the entire caliper.

If you’re also replacing the rotors, you’ll need to remove the caliper bracket. This is usually held in place by two bolts. Once the bracket is off, the rotor should slide right off the wheel hub. If it’s stuck due to rust, you may need to tap it gently with a rubber mallet to loosen it.

Important: Always replace brake pads in pairs (both rear wheels) to ensure even braking performance.

Inspecting and Cleaning Components

Before installing new parts, it’s crucial to inspect and clean the existing components. Use a wire brush to clean any rust or debris from the caliper bracket and the area where the rotor sits on the hub. This ensures proper fitment of the new parts and prevents issues like brake squealing or uneven wear.

Check the caliper slide pins for smooth movement. If they’re sticking or show signs of corrosion, clean them thoroughly and apply a thin layer of high-temperature brake grease. This step is critical for proper caliper operation and even pad wear.

Inspect the brake hoses for any cracks, bulges, or signs of leakage. While you have easy access, it’s a good time to check these components. If you notice any issues, it’s best to replace the hoses before reassembling the brakes.

Pro tip: Use brake cleaner on a rag to wipe down the hub surface where the new rotor will sit. A clean surface ensures proper rotor installation and prevents vibration issues.

Installing New Rotors and Brake Pads

If you’re installing new rotors, now is the time to do so. Slide the new rotor onto the wheel hub, making sure it sits flush. If there’s any resistance, check for debris or rust on the hub surface. Some new rotors come with a protective oil coating that must be removed before installation. Use brake cleaner to thoroughly clean the rotor surfaces.

Next, reinstall the caliper bracket if you removed it. Torque the bolts to the manufacturer’s specifications using a torque wrench. This step is crucial for safety and proper brake operation.

Now, focus on the new brake pads. Apply a thin layer of brake lubricant to the backs of the pads and any contact points with the caliper bracket. This helps prevent squeaking and ensures smooth operation. Install the new pads into the caliper bracket, making sure they’re oriented correctly.

Before reinstalling the caliper, you’ll need to retract the caliper piston to make room for the new, thicker pads. Use a C-clamp or a specialized caliper piston tool for this task. Slowly compress the piston back into the caliper housing. If you’re working on the rear brakes, you may need to turn the piston as you compress it, as some rear calipers have a screw-in design.

Caution: As you compress the caliper piston, keep an eye on the brake fluid reservoir. The fluid level will rise as the piston is pushed back. You may need to remove some fluid to prevent overflow.

Reassembly and Final Steps

With the new pads in place and the caliper piston retracted, you can now reinstall the caliper. Slide it over the new pads and secure it with the caliper bolts. Ensure the bolts are tightened to the correct torque specification.

Before putting the wheel back on, double-check all your work. Make sure all components are secure and properly aligned. Spin the rotor by hand to ensure it rotates freely without any rubbing or resistance.

Reinstall the wheel and hand-tighten the lug nuts. Lower the vehicle back to the ground and use a torque wrench to tighten the lug nuts to the proper specification. It’s important to tighten them in a star pattern to ensure even pressure.

The final step is to pump the brake pedal several times to re-establish proper pedal feel. This process pushes the caliper piston back out and brings the pads into contact with the rotor. Check the brake fluid level one last time and top it off if necessary.

Important: After replacing your brakes, it’s crucial to “bed” the new pads and rotors. This process involves a series of controlled stops to properly seat the pads and rotors together. Consult your vehicle’s manual or the brake pad instructions for the specific bedding procedure.

Testing and Maintenance

After completing the brake replacement, take your vehicle for a test drive in a safe area. Start with gentle braking to ensure everything feels normal. Gradually increase your braking force to test the new components under various conditions. Listen for any unusual noises and pay attention to how the brake pedal feels.

Regular maintenance is key to prolonging the life of your new brakes. Here are some tips:

- Avoid sudden, hard stops whenever possible

- Listen for any unusual noises when braking

- Periodically check for even pad wear

- Clean your wheels regularly to minimize brake dust buildup

By following these steps and maintaining your brakes properly, you can ensure safe and effective braking performance for years to come. Remember, if you’re ever unsure about performing this task yourself, it’s always best to consult a professional mechanic.

FAQs About How To Replace Rear Brakes

- How often should rear brakes be replaced?

Typically, rear brake pads need replacement every 30,000 to 70,000 miles, depending on driving habits and vehicle type. - Can I replace just one side of the rear brakes?

It’s recommended to replace both sides simultaneously to ensure even braking performance and wear. - How long does it take to replace rear brakes?

For a DIY job, expect to spend 2-4 hours, depending on your experience and the vehicle’s complexity. - Do I always need to replace the rotors when changing brake pads?

Not always, but it’s often recommended if the rotors are worn, warped, or have reached their minimum thickness. - What are signs that I need to replace my rear brakes?

Squealing noises, reduced braking performance, and a pulsating brake pedal are common indicators of worn brakes.